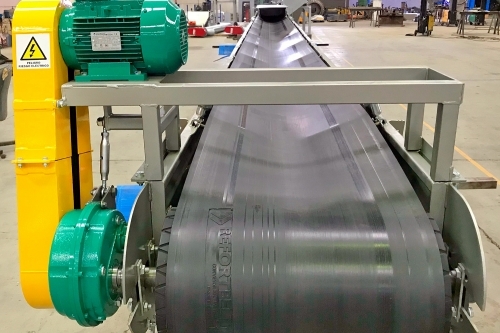

Redler conveyors have applications in the filling, distribution and emptying of bulk products, such as pomace or cereals, in hoppers and silos.

They are highly robust machines that move the product horizontally or with little inclination. Throughout the machine, several unloading points can be installed.

A diferencia de las cintas transportadoras, con los redlers se consigue estanqueidad y hermeticidad. Esta característica lo convierte en un transporte seguro para todo tipo de materiales, ya que su sistema de estanqueidad protege el material de las inclemencias del entorno. Además, no generan polvo o materiales en suspensión en la línea de transporte.

Unlike conveyor belts, with redlers tightness and hermeticity are achieved. This characteristic makes it a safe transport for all types of materials, since its sealing system protects the material from the elements of the environment. In addition, they do not generate dust or suspended materials in the transport line.

Enables large-scale separation of solids and liquids

One step further

The drag system is carried out by means of chains and not with a conveyor belt. These chains facilitate and ensure a uniform and constant advance of the product inside the conveyor.

The dimensions of width and height, the capacity and the transport speed, will depend on the product and the specific needs of each installation.

Personalized maintenance

To guarantee long-lasting operation and 100% performance, we carry out comprehensive maintenance, from the replacement of chains and rollers, to the replacement of bearings, as well as any damaged part.

Industrial machinery repair

By having a team of qualified professionals, we know the complexity of industrial facilities and the logistical work involved in disassembling and moving parts for repair. Due to this, our company carries out maintenance work on site, so that you save on expenses and time invested.

Project review and planning

The Consulting and Engineering service that we offer at CHIA covers a wide range of knowledge and technology made available to our clients. We help companies during all stages of the project, from advice and planning to the commissioning of all facilities and machinery.

Plant machinery maintenance

At CHIA we are aware of the need to be able to guarantee the proper functioning of the machinery. For this reason, we offer a personalized, efficient maintenance service in the place where the machinery is located.

On-site balancing service

We offer a complete dynamic and static balancing service, as well as advice on issues related to vibration problems in rotating elements and a maintenance service that will prolong the useful life of your machinery. The main balancing services we offer are:

- Static and dynamic bench balancing

- Overspeed tests

- Modal analysis

- Vibration and wear control

- Balanced on site

Drippings

A good blasting system is essential for the maintenance and proper functioning of machinery and parts. With this process, we can remove calamine, remove rust, clean surfaces damaged by work and the passage of time or improve the condition of the machinery.

At CHIA we have medium and high flow compressors, as well as a tunnel equipped with two automatic loading machines to optimize time and costs, which allow the stripping of any surface by spraying abrasives at high pressure.

Vulcanized Band Splices

We are experts in vulcanized belt splices. Our experience and advanced technology will enable us to provide you with fast and efficient splicing services. You will be able to choose between cold vulcanized splicing - it is done through the use of chemical products- or hot - through the use of heat and pressure through the use of a vulcanization press.

Personalized Customer Service

We are aware that a personalized treatment and active advice are the best ways to develop our clients' ideas and that the result fulfils the needs of the project.

At CHIA we adapt to the client's needs, economic system and execution deadlines to guarantee satisfaction at all times.

Personalized maintenance

To guarantee long-lasting operation and 100% performance, we carry out comprehensive maintenance, from the replacement of chains and rollers, to the replacement of bearings, as well as any damaged part.

Certification

and guarantee

We have the UNE ISO 9001:2015 and ISO 17065 certification to guarantee the highest quality and safety in the manufacturing, maintenance and balancing processes of industrial machinery in a personalised and efficient way.

Last projects

Buenache de Alarcón (Cuenca)

2025

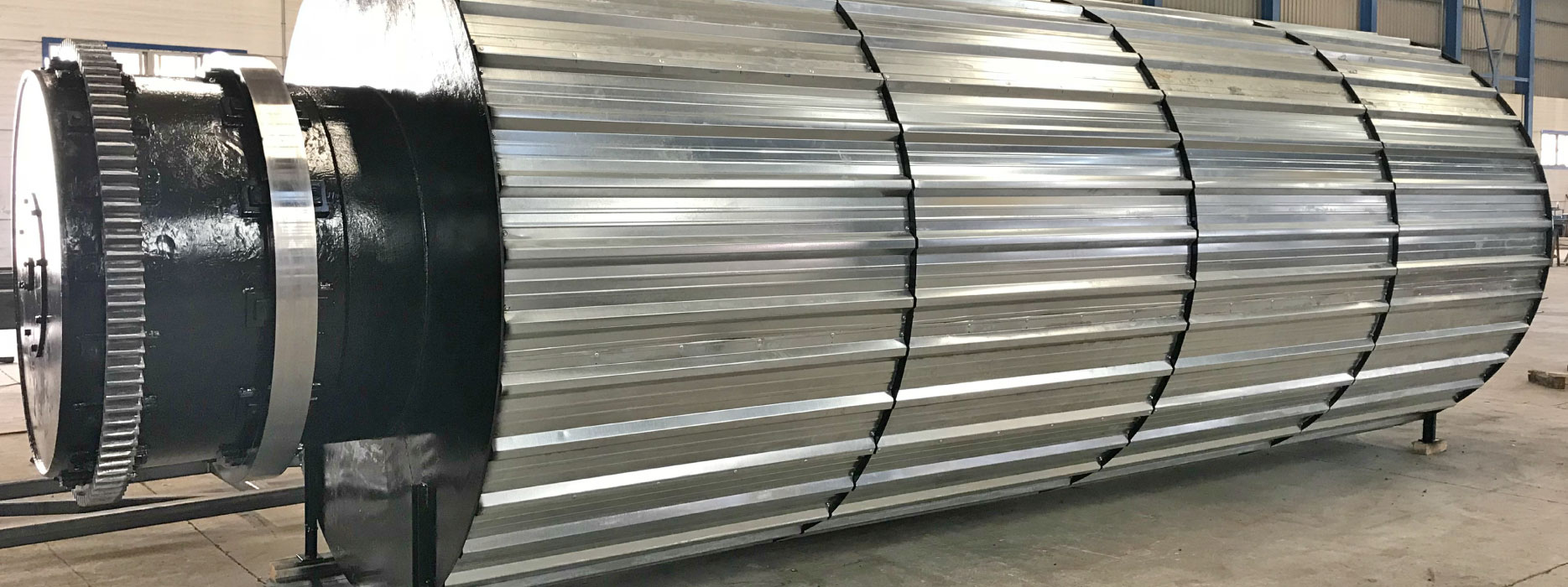

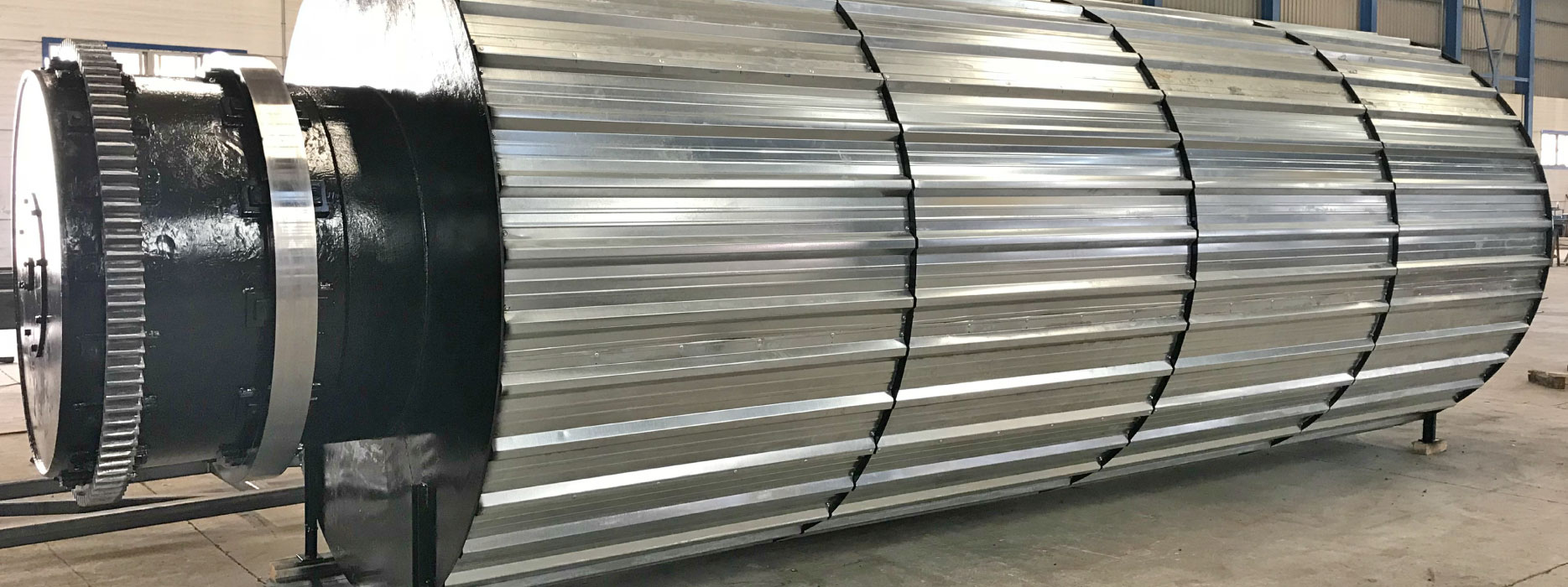

S-12000 INOX Trommel Dryer Line

Greece

2017

Production of deboning machines

México

2017

Avocado dryer

Tunisia

2017

Conveyor belt for wet pomace transport

Morocco

2016

Fertilizer bagging system

Navarra

2016

Olive pomace drying system

Chile

2011

Olive bone drying system

Portugal

2011

3 lines of alpeorujo dryers

Linares (Jaen)

2008

Belts in an alpeorujo treatment factory

Madagascar

2003

Construction of redlers and endless conveyor

Last project

Buenache de Alarcón (Cuenca)

2025

S-12000 INOX Trommel Dryer Line

see project

Greece

2017

Production of deboning machines

see project

México

2017

Avocado dryer

see project

Tunisia

2017

Conveyor belt for wet pomace transport

see project

Morocco

2016

Fertilizer bagging system

see project

Navarra

2016

Olive pomace drying system

see project

Chile

2011

Olive bone drying system

see project

Portugal

2011

3 lines of alpeorujo dryers

see project

Linares (Jaen)

2008

Belts in an alpeorujo treatment factory

see project

Madagascar

2003

Construction of redlers and endless conveyor

see project

Drum dryer for industrial drying

17 de febrero de 2026

Separates solids and liquids through the controlled application of heat, ensuring uniform drying.

Read NewsTipos de bandas para cintas transportadoras: soluciones para cada necesidad

31 de julio de 2025

En CHÍA, diseñamos cintas transportadoras a medida, adaptadas a todo tipo de instalaciones industriales.

Read NewsBoosting agricultural modernization: aid from the regional government of Andalusia and Espirales CHÍA's technology

27 de marzo de 2025

The agricultural sector is one of the fundamental pillars of the Andalusian economy, and its modernisation is key to guaranteeing its competitiveness and sustainability.

Read NewsVulcanised belt splices: the customised service of Espirales CHÍA

20 de enero de 2025

At Espirales CHÍA, we are specialists in the maintenance and repair of conveyor belts, and one of the services most requested by our customers is vulcanised splices.

Read NewsBy preparing your machinery for Orujo Campaign with personalised maintenance

15 de agosto de 2024

Coming agricultural campaigns are crucial, especially in oil sector, where pomace plays an essential role.

Read NewsDrum dryer for industrial drying

17 de febrero de 2026

Separates solids and liquids through the controlled application of heat, ensuring uniform drying.

Read NewsTipos de bandas para cintas transportadoras: soluciones para cada necesidad

31 de julio de 2025

En CHÍA, diseñamos cintas transportadoras a medida, adaptadas a todo tipo de instalaciones industriales.

Read NewsBoosting agricultural modernization: aid from the regional government of Andalusia and Espirales CHÍA's technology

27 de marzo de 2025

The agricultural sector is one of the fundamental pillars of the Andalusian economy, and its modernisation is key to guaranteeing its competitiveness and sustainability.

Read NewsVulcanised belt splices: the customised service of Espirales CHÍA

20 de enero de 2025

At Espirales CHÍA, we are specialists in the maintenance and repair of conveyor belts, and one of the services most requested by our customers is vulcanised splices.

Read NewsBy preparing your machinery for Orujo Campaign with personalised maintenance

15 de agosto de 2024

Coming agricultural campaigns are crucial, especially in oil sector, where pomace plays an essential role.

Read News